Enhance Metal Fabrication Efficiency with Advanced Deburring Machines

Apr 29 ,2025

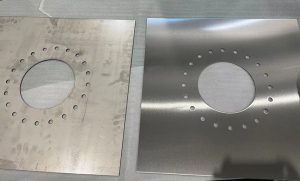

In modern metal fabrication, achieving flawless surfaces is critical for product quality and safety. Deburring machines, such as metal linish machines, metal brush machines, and automatic metal sheet brush machines, play a pivotal role in removing burrs, flash, and imperfections from materials like steel, aluminum, and copper. This article explores how these machines optimize production and what to consider when investing in a sheet brushing machine for your workshop.

Key Materials Processed by Deburring Machines

Deburring equipment is versatile, handling a range of materials:

- Steel (Carbon & Stainless): Ideal for metal fabrication machines, deburring ensures smooth edges after cutting or welding, preserving corrosion resistance.

- Aluminum: Lightweight yet prone to burrs, aluminum sheets benefit from automatic metal sheet brush machines to maintain aerospace and automotive standards.

- Copper & Brass: Precision deburring avoids electrical faults in electronics, achievable with specialized metal brush machines.

- Cast Iron: Heavy-duty sheet brushing machines efficiently clean large castings, improving surface quality for machinery components.

- Plastics: Advanced models now deburr plastic parts post-molding, expanding their industrial applications.

Why Choose Automated Deburring Solutions?

- Boost Productivity: Automatic metal sheet brush machines streamline high-volume tasks, reducing manual labor and errors.

- Precision & Consistency: Metal linish machines deliver uniform finishes, critical for tight-tolerance components.

- Durability: Built for rigorous use, these machines minimize downtime in demanding metal fabrication environments.

Selecting the Right Deburring Machine

- Type: Match needs to equipment like sheet brushing machines (for large sheets) or compact edge deburrers.

- Material Compatibility: Verify the machine handles your primary materials (e.g., stainless steel, aluminum).

- Automation Level: High-output facilities benefit from fully automated systems, while smaller shops may prefer semi-automatic models.

- Safety & Eco-Friendliness: Opt for machines with dust extraction and noise reduction to meet workplace regulations.

ROI & Long-Term Benefits

Investing in a metal fabrication machine like ADV’s deburring solutions not only enhances product quality but also reduces long-term costs. Automated systems lower labor expenses, while durable builds ensure years of reliable service.

From metal linish machines to specialized sheet brushing machines, modern deburring technology is essential for precision-driven industries. By integrating automated solutions like automatic metal sheet brush machines, manufacturers achieve superior finishes, faster turnaround, and compliance with safety standards.