How the Automatic Zinc Aluminum Sanitary Faucet Six-Axis CNC Polishing Machine Revolutionizes Metal Finishing

Jul 11 ,2025

Introduction to CNC Technology in Metal Finishing

Computer Numerical Control (CNC) has fundamentally transformed metalworking processes. Unlike traditional manual methods, CNC systems execute programmed instructions with micron-level accuracy, enabling complex operations impossible through conventional techniques.

Overview of CNC Machining Technology

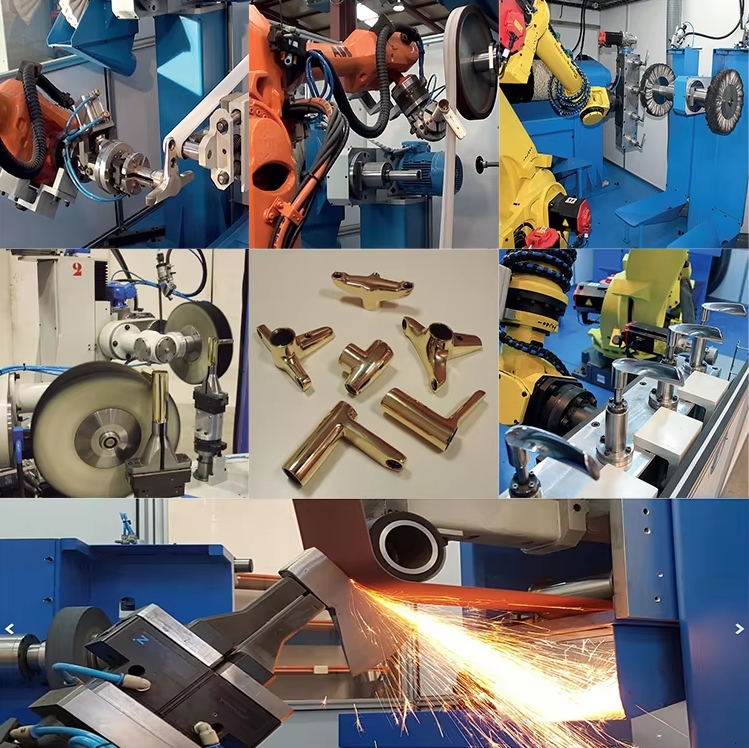

Definition and Functionality: CNC polishing machines utilize computerized controls to manipulate polishing tools across multiple axes of motion. The six-axis configuration provides complete spatial freedom, allowing the polishing head to approach workpieces from virtually any angle.

Historical Development: From rudimentary three-axis systems in the 1960s to today’s sophisticated six-axis robotics, CNC polishing has evolved to handle complex geometries with increasing automation and precision.

Importance of CNC in Metal Finishing

Modern manufacturing demands solutions that combine precision with productivity:

Enhancing Manufacturing Efficiency

Six-axis CNC machines operate continuously with minimal supervision, reducing production cycle times by up to 70% compared to manual polishing. Automated tool changing and programmable workflows enable lights-out manufacturing capabilities.

Reducing Labor Costs

By automating the most labor-intensive finishing process, manufacturers reduce skilled labor requirements by 60-80%. The system’s consistency also eliminates the costs associated with human error and retraining.

The Six-Axis Advantage for Zinc Aluminum Faucets

Sanitary faucets present unique finishing challenges due to their complex curves, tight tolerances, and hygienic surface requirements. The six-axis CNC polishing machine addresses these perfectly:

Complete Surface Coverage

The additional rotational axes (beyond standard 3-axis machines) enable the polishing head to maintain optimal contact angle with complex faucet contours, including internal channels and tight radii.

Material-Specific Processing

Specialized programming accommodates the unique properties of zinc aluminum alloys, applying precise pressure and motion profiles to prevent overheating while achieving mirror finishes.

Hygienic Surface Perfection

Automated micro-polishing eliminates microscopic pores where bacteria can grow, meeting medical-grade sanitary standards crucial for faucet manufacturing.

Transformative Benefits in Metal Finishing

Unmatched Precision

Maintains tolerances within ±0.005mm across complex geometries, ensuring perfect dimensional accuracy for mating components.

Consistent Quality

Eliminates human variability, producing identical surface finishes on every workpiece regardless of production volume.

Material Savings

Precision material removal minimizes waste of expensive zinc aluminum alloys by 25-40% compared to manual methods.

Reduced Environmental Impact

Closed-loop cooling and automated abrasive management systems significantly reduce wastewater and consumable waste.

The Future of Metal Finishing

The automatic six-axis CNC polishing machine represents more than an incremental improvement – it’s a paradigm shift in metal finishing technology. For manufacturers of zinc aluminum sanitary faucets, this technology delivers:

- 40-60% reduction in finishing labor costs

- 3-5x increase in production throughput

- Consistent medical-grade surface finishes

- 30% reduction in material waste

- Ability to create previously impossible surface geometries

As CNC technology continues advancing with AI integration and IoT connectivity, the automatic six-axis polishing machine establishes a new standard for precision metal finishing that will shape manufacturing excellence for decades to come.