Why Maintenance Matters

Proper maintenance of long belt polishing machines directly impacts production quality and operational costs. A well-maintained system delivers consistent finish quality while minimizing unexpected downtime.

Enhancing Manufacturing Efficiency

- Maintain consistent surface finish quality across production batches

- Reduce material waste from polishing errors by 18-25%

- Optimize energy consumption through calibrated machine operation

Reducing Operational Downtime

- Prevent unexpected breakdowns that halt production lines

- Extend equipment lifespan by 30-40% with proper care

- Minimize expensive emergency repairs through proactive maintenance

Cleaning & Preventive Maintenance

Dust Collection Systems

- Clean filters weekly using compressed air at ≤80 PSI

- Inspect ductwork monthly for obstructions or leaks

- Replace HEPA filters every 400-500 operating hours

- Monitor suction pressure gauges for performance consistency

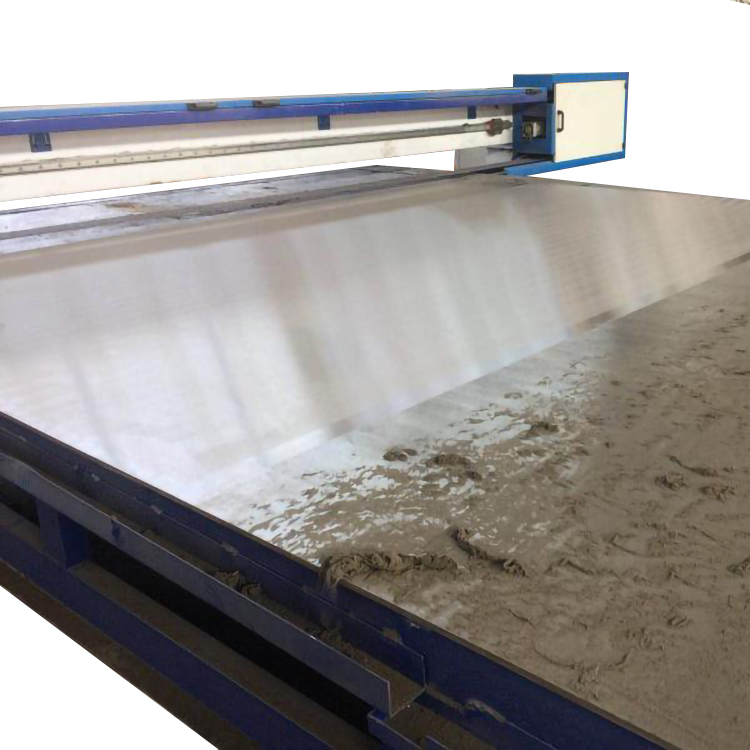

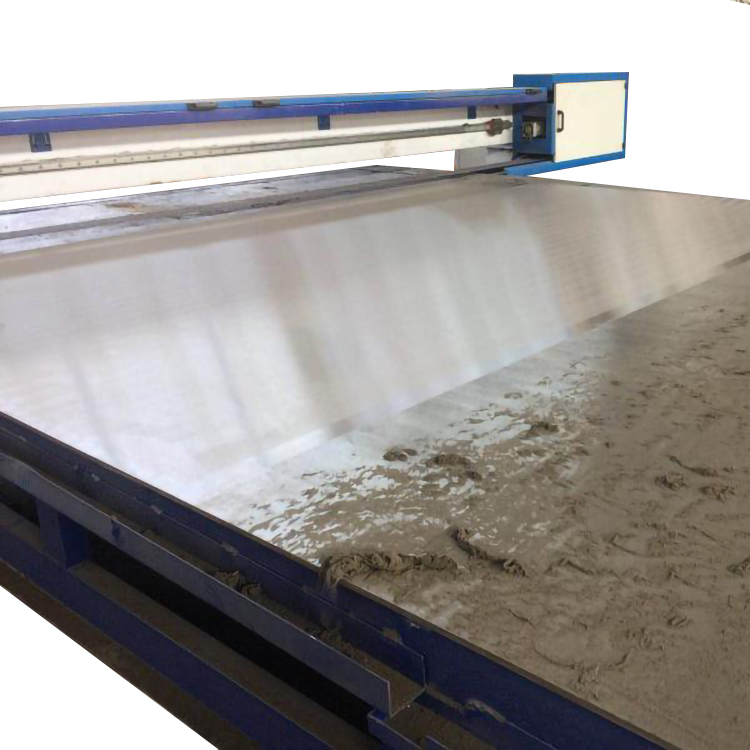

Conveyor Belt Care Protocol

- Daily belt tension checks with calibrated tension gauge

- Weekly cleaning with manufacturer-approved solutions

- Monthly inspection for edge wear, cuts, and surface degradation

- Quarterly alignment verification using laser alignment tools

Recommended Maintenance Schedule

| Frequency |

Task |

Performance Metric |

| Daily |

Belt tension check, Dust collection inspection |

±5% tension variance |

| Weekly |

Full system cleaning, Lubrication points |

0 residue buildup |

| Monthly |

Motor inspection, Drive component alignment |

<0.005″ misalignment |

| Quarterly |

Complete system calibration, Wear components replacement |

Specification compliance |

Tool Inspection & Optimization

Identifying Polishing Tool Wear

- Measure abrasive belt thickness with digital calipers monthly

- Check for glazing or clogging of abrasive surfaces

- Monitor polishing consistency across workpiece width

- Track production output per belt for wear patterns

Precision Tool Alignment

- Use laser alignment tools for contact wheel positioning

- Verify platen flatness with straight edge quarterly

- Calibrate pressure application systems bi-monthly

- Check tracking adjustment mechanisms for smooth operation

Material-Specific Best Practices

Material Compatibility

- Stainless Steel: Use silicon carbide abrasives

- Aluminum: Employ non-loading zirconia belts

- Plastics: Utilize fine-grit ceramic abrasives

- Wood Composites: Apply specialized grain-raising belts

Optimal Settings Guide

| Material |

Belt Speed |

Contact Pressure |

| Stainless Steel |

25-35 m/s |

High |

| Aluminum |

20-28 m/s |

Medium |

| Plastics |

15-22 m/s |

Low |

| Wood Composites |

18-25 m/s |

Medium-High |

Automated System Maintenance

Automation Benefits

- 15-30% increased consistency in finish quality

- 20% reduction in operator fatigue errors

- Precise repeatability for high-volume production

- Integrated quality monitoring capabilities

Automated Feature Maintenance

- Monthly calibration of pressure sensors

- Quarterly inspection of servo motor drives

- Bi-annual replacement of position encoders

- Annual software updates and backup

Troubleshooting & Quick Fixes

Common Operational Issues

- Belt tracking problems: Adjust tension rollers

- Inconsistent finish: Check abrasive wear patterns

- Overheating workpieces: Reduce feed rate or pressure

- Vibration issues: Balance contact wheels

Maintenance Quick Fixes

- Belt slippage: Increase tension 5-10% incrementally

- Dust collection failure: Clear filter clogging immediately

- Surface scratches: Replace worn platen covers

- Motor overheating: Clean ventilation ports

Proactive Maintenance Planning

Implementing a structured maintenance program extends equipment lifespan and maintains consistent finish quality:

- Develop customized maintenance checklists for each machine

- Maintain digital maintenance logs with performance metrics

- Train operators on basic troubleshooting procedures

- Stock critical spare parts to minimize downtime

- Schedule professional calibration annually

Proactive maintenance reduces repair costs by 40-60% and extends equipment service life by 3-5 years.